| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Packaging Details : wooden case packing

Supply Ability : 30 Piece/Pieces per Quarter

Price : USD10,000-80,000/SET

Brand Name : Jingtan

Certification : CE

MOQ : 1 set

Delivery Time : 60 days

Payment Terms : L/C/T/T

place of origin : Hunan, China

type : Induction Furnace

usage : deposition furnace

video outgoing-inspection : Provided

machinery test report : Provided

core components : PLC

brand name : OEM

voltage : 380V

weight (t) : 2 T

power (kw) : 160

warranty : 1 Year

key selling points : Easy to Operate

Application 1 : metal halides

Application 2 : metallic organic compounds

Carbon source : hydrocarbons(C3H8)

Application 3 : C/C composition material

Application 4 : SIC composite materials

Condition : New

Marketing Type : Ordinary Product

Warranty of core components : 1 Year

Showroom Location : Romania, Nigeria

Applicable Industries : semiconductor industry

Customized Gradient Sediment Or Mixed Coating Vapor Deposition Furnace

Feature 1:

Feature 2:

4) The use of plasma and laser assisted technology can significantly promote the chemical reaction, so that the deposition can be carried out at a lower temperature.

5) The chemical composition of the coating can change with the change of the gas phase composition, so as to obtain gradient sediment or mixed coating.

6) can form a variety of metal, alloy, ceramic and compound coatings through various reactions.

Feature 3:

7) round the plated parts. It can be coated on complex shape matrix and granular material. Suitable for coating all kinds of complex shapes of the workpiece. Because of its good coating performance, it can be coated with grooves, grooves, holes, and even

blind holes of the workpiece.

8) The deposited layer usually has a columnar crystal tructure and is not resistant to bending, but its structure can be improved by gas phase perturbation of the chemical rection through various techniques.

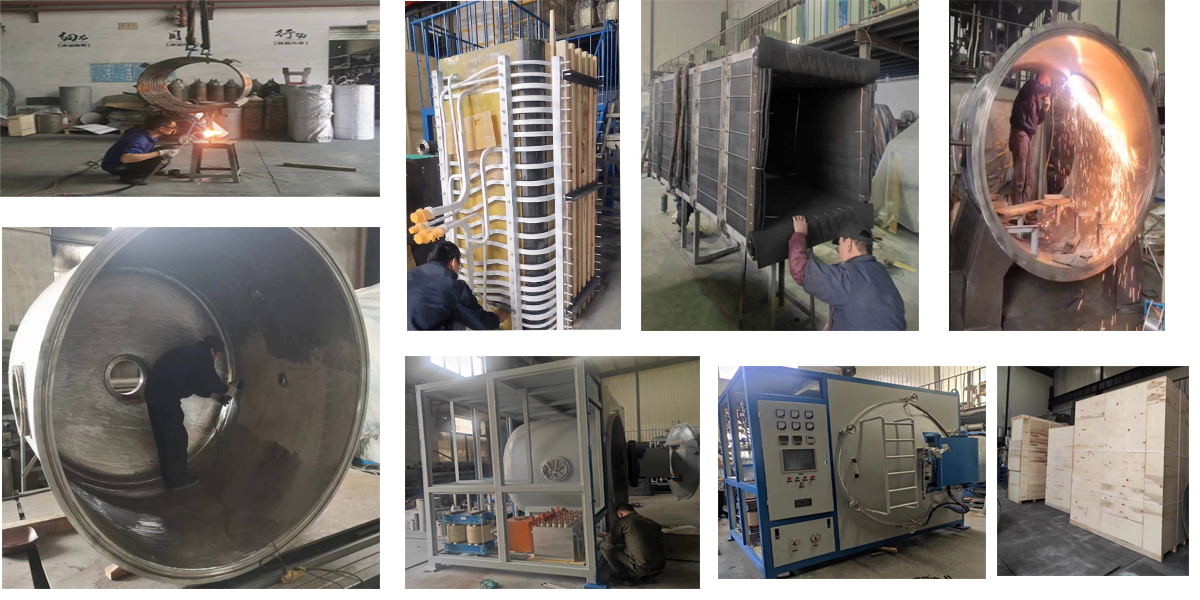

Customers Photos

Customers Photos  Customer cooperation cases:

Customer cooperation cases: Contact Information as follow:

Contact Information as follow:

|

|

Customized Vapor Deposition Furnace Gradient Sediment Or Mixed Coating For Metal Halides Images |